Gone to Seed: The Human Cost of Recycled Cotton

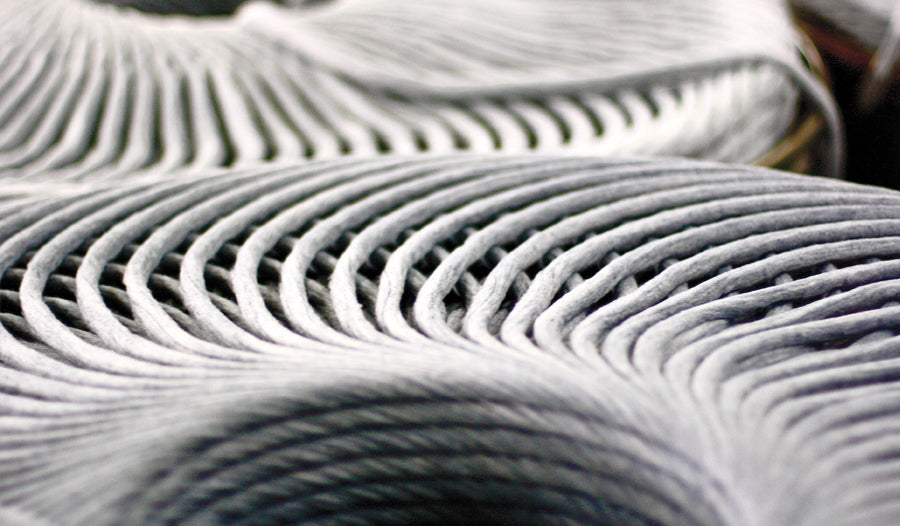

Image: Recycled cotton rovings

Image: Recycled cotton rovings

When writing Issue 100 Anniversary we took the opportunity to pause and reflect on what has changed since we published our first issue in 2003. Back at the turn of the millennium, we were blinded by overconsumption and gave scant regard to the environmental and social cost of mass production. We therefore decided to focus on cotton in this issue, a fibre whose history is entangled with that of slavery and environmental destruction. In this excerpt below, Alden Wicker explores the latest innovations in the pursuit of a sustainable fibres and the human cost of recycled cotton. Read the article in its entirety in Issue 100 Anniversary.

Everyone in the fashion world wants to find a more sustainable, environmentally friendly way to make cotton clothes — or a benign (and comfy) alternative. Some are on the brink of succeeding. But almost no one understands the social cost of these innovations.

Image: Satellite image of the shrinking of the Aral Sea taken in 2015. Formally one of the four largest lakes in the world with an area of 68,000 km², the Aral Sea has been steadily shrinking since the 1960s after the rivers that fed it were diverted by Soviet cotton irrigation projects.

Today, the agro-industrial complex that has grown up around cotton has been dogged with everything from human rights abuses to its own environmental harms. Just the farming of cotton depletes increasingly scarce water supplies and spreads pesticide residue. The half-dried-up Aral Sea has been a public relations nightmare for the industry. So have child labour and farmer suicides in India. Forced Uighur labour in China is just the latest cotton indignity. Fashion brands would rather not deal with cotton’s PR problems, or its fluctuating costs; thus, the rise of polyester and rayon. Now comes a company like re:newcell with a more efficient way to recycle cotton clothing. But its process is still dependent on cotton. So everyone’s still searching for the desperately needed innovation: a soft, high performing, non-polluting material that can truly replace cotton.

Image: A farmer harvesting organic cotton on their family farm in Sendhwa, India.

Material Scientist Professor Ali Harlin believes that many of the old viscose-rayon factories dotting Finland could easily and cheaply be retrofitted to produce Infinited Fibre, a cellulose carbamate fibre that looks and feels exactly like cotton. And here’s the best part: as its name implies, Infinited’s process can use any kind of cellulose an infinite number of times. That means all kinds of castoffs could be used, reused, and continually reused to make more clothing. This seems like an enormous win-win-win. There is a not-so-small problem, however. After sustaining cultures in myriad corners of the world for thousands of years, the cotton trade is now woven into our global economy. Today, an estimated 300 million people work in the cotton industry, which raises a question: What will happen to the world’s cotton farmers?

This is an excerpt of an edited article from Craftsmanship Quarterly that is published in Issue 100 Anniversary. Find out how to read the rest of the article here.